How 3D Printing works: Things You Should Know About the New Technology

Posted on Tuesday 16 July, 2019

Artists may be experts at drawing and colouring life-like objects, but if you ask them to replicate the art in three-dimensional form, it will not be an easy task. For many companies, developing a prototype or a model that a client can physically touch, observe and handle is important. Building something like that is usually a long and time-consuming task and very expensive. The simple solution for this is to use a 3D printer and the technology created to address this problem is called ‘3D printing’. It is possible to build three-dimensional models by using suitable materials and the specified shape and structure chosen in the computer and linked to the 3D printer

It is an additive process that builds an object by adding layer upon layer. In other words, it is the opposite of subtractive manufacturing method, which starts off with a piece of material and continues hollowing it out until it assumes a certain shape. The printer continues the process until the object takes up its final shape. 3D printing is capableof designing complex shapes with lesser materials than consumed in traditional manufacturing processes.

These days we find cheap and high-range 3D printers in online as well as regular stores at unbelievable prices. If you’re interested in investing in a 3D printer either for personal or business purpose, it is a good idea to get a basic understanding of the printer and its operation.

How 3D Printers Work

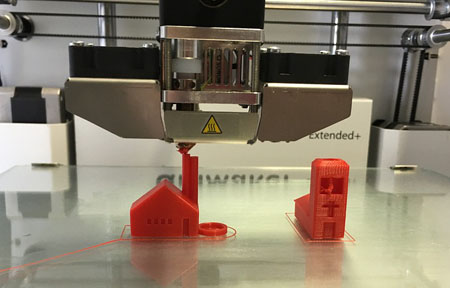

A 3D printer is a machine that is capable of creating objects out of different types of materials, most of which are plastics.

The 3D printing technology is pretty simple and straightforward. You design a 3D object in a computer and then connect it to a 3D printer and then wait for the model to be constructed by linking together layers that solidify into an object. The printer is capable of replicating even complex parts, including moveable wheels, brakes, and pedals without using any tools.

If you use a microscope to look at words in a printed paper, you’ll notice that even though it appeared flat, observed closely, it looks like a raised projection. Imagine stacking up enough layers of ink one on top of another until it is possible to build the 3D model. The first 3D printers worked on this premise, building a physical object out of several tiny layers.

Materials Used in 3D Printing

You might be tempted to think that a 3D printer would use ink similar to an inkjet or laser printer. An inkjet printer uses liquid ink spray for printing while a laser printer uses solid powder. A 3D printer is unique because it uses molten plastic that is forced out through a tiny nozzle. The plastic used for the purpose is called ‘thermoplastics’ that melt when heated and turn solid upon cooling. The most common thermoplastic favoured for 3D printing is called ABS.

Importantly, once the plastic has set into a solid model, it can even be sanded smooth or painted upon. It is also a great material that accepts all kinds of colors. The plastic is usually fed inside as pellets or filaments. Theoretically, you can print with anything that have similar properties – that is liquid when heated and strong solid upon cooling.

Advantages and Disadvantages of 3D Printing

There are quite a few advantages of 3D printing. This includes:

1. 3D printing is supposed to be about 10 times faster and 5 times cheaper than other methods. This is useful for people who want to construct many prototypes in a short span. Even considering that high-end 3D printers are priced in the range of $25,000 - $50,000 range, it is still much cheaper than sophisticated a rapid prototyping (RP) machines that can cost $100,000 to $500,000.

2. 3D printers are compact, easy to use and safe from beginners to experts. Many design and engineering schools now equip their laboratories with 3D printers to train their students.

3. Companies use 3D printers for fast and cheap prototyping that takes only a few hours to days compared to weeks and there is no need for expensive molds or additional tools. This makes it suitable for small batch or trial run manufacturing.

Looking at the disadvantages, here are a few:

1. The finished product of a 3D printer is much inferior in quality compared to what a RP printer can achieve.

2. There is a limit to the type of materials that can be used in a 3D printer. A RP machine can use a range of materials to build large-sized models.

3. A 3D printer can print products of only a certain size in contrast to high end RP models that can build huge models using any materials. It must also be noted that the finish and texture is cruder in a 3D printer.

Applications of 3D Printing

Many industries apply 3D printing for different purposes, such as:

- Braces and aligners in dentistry

- Lamp/furniture design

- Scale building models in architecture

- Movie props in media technology

- Fossil reconstruction in palaeontology

- Ancient artifacts replication in archaeology

- Bone and evidence reconstruction in forensic pathology

- Design of eyewear and prosthetics

Future Prospects for 3D Printing

Many people in the technology field believe that 3D printing holds a lot of scope for bringing about a revolution in the manufacturing industry. While it is possible that 3D printing will be affordable enough in the near future to allow everyone to make their own 3D models at home or even for children’s craft projects, there are limitations to the technology. A simple printer and plastic can achieve only so much even after multiple technology updates.

Looking at the bigger picture, 3D printing will be economically beneficial when most companies decide to adopt the technology in their manufacturing processes. As a robotic technology, it can slowly replace poor-paid labor force in countries like India and China. A manufacturer will be able to offer better customization and higher affordability of products and lower manufacturing cost by using 3D printing.

Any comments?